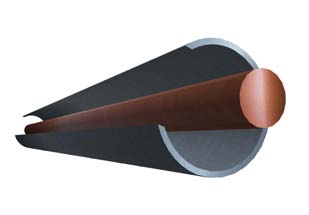

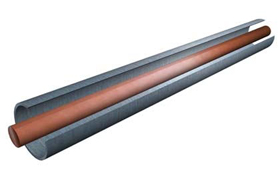

LX103 nickel-aluminum wire is a new kind of cored wire for flame spray application developed by Langqiao Surface Technology Co. It refers to the production method of cored wire for welding, but instead of nickel powder filled in Aluminum tube, it is filled with a solid nickel wire in the hollow tube, and so becomes a HARD-cored wire with a solid nickel wire en-wrapped by aluminum tape.

The new process for making nickel-aluminum wire has two advantages which dedicated to a better coating:

1. Cored wire filled with powder may affect the coating’s homogeneity due to the leakage or dissociation of powders from the tube, but will never happen with solid cored wire.

2. The two metals (nickel and aluminum) bond together to produce LX103 are unalloyed fresh metals. Compared with nickel aluminum alloyed wire, a stronger exothermal reaction occurs during combustion process when using LX103 and thereby resulting in a better coating adhesion.

The LX103 cored wire is recommended to be used as the flame spray material for bond coating overlay. Besides the high bonding strength and high temp corrosion resistant properties, the coating obtained by flame spraying with LX103 also shows a higher hardness which is in the range of HRC45-50.