In 2017, with the strengthening of the country's efforts in environmental protection, the field for manufacturing of power generation equipment is harboring with significant changes. Some inefficient coal-fired power generation equipment with substandard emissions need to achieve emission reduction and efficiency increase through technological transformation. At the same time, some private gas turbine enterprises have seen the positive future of natural gas power generation and are quickening their pace to build gas turbines with independent intellectual property rights of China to meet the upcoming wave of coal to gas. And all of these need the support of thermal spray technology.

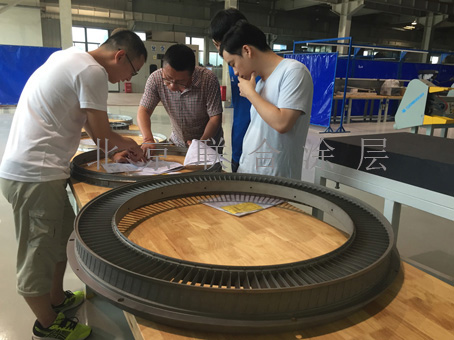

As a professional manufacturer engaged in the manufacturing of thermal spraying materials and service in China for nearly 20 years, UCT not only provides first-class thermal spray services for the global OEMS and domestic power plant equipment manufacturers, but also develops the powder material for abradable coating that can replace those expensive imported counterparts. At present, UCT has developed the abradable coating materials like LF105, LF109, LF231 etc. which can replace Metco320, Metco601 and Metco301 respectively. At present, the customers of UCT’s abradable coating processing include global OEMs, CPP, HTC, Fu-An Gas Turbine and so on.

UCT is willing to redouble our effort and work together with numerous power plant equipment manufacturers to develop more qualified coating materials and to create much better coating quality to make our due contributions to China's power generation and environment improvement.